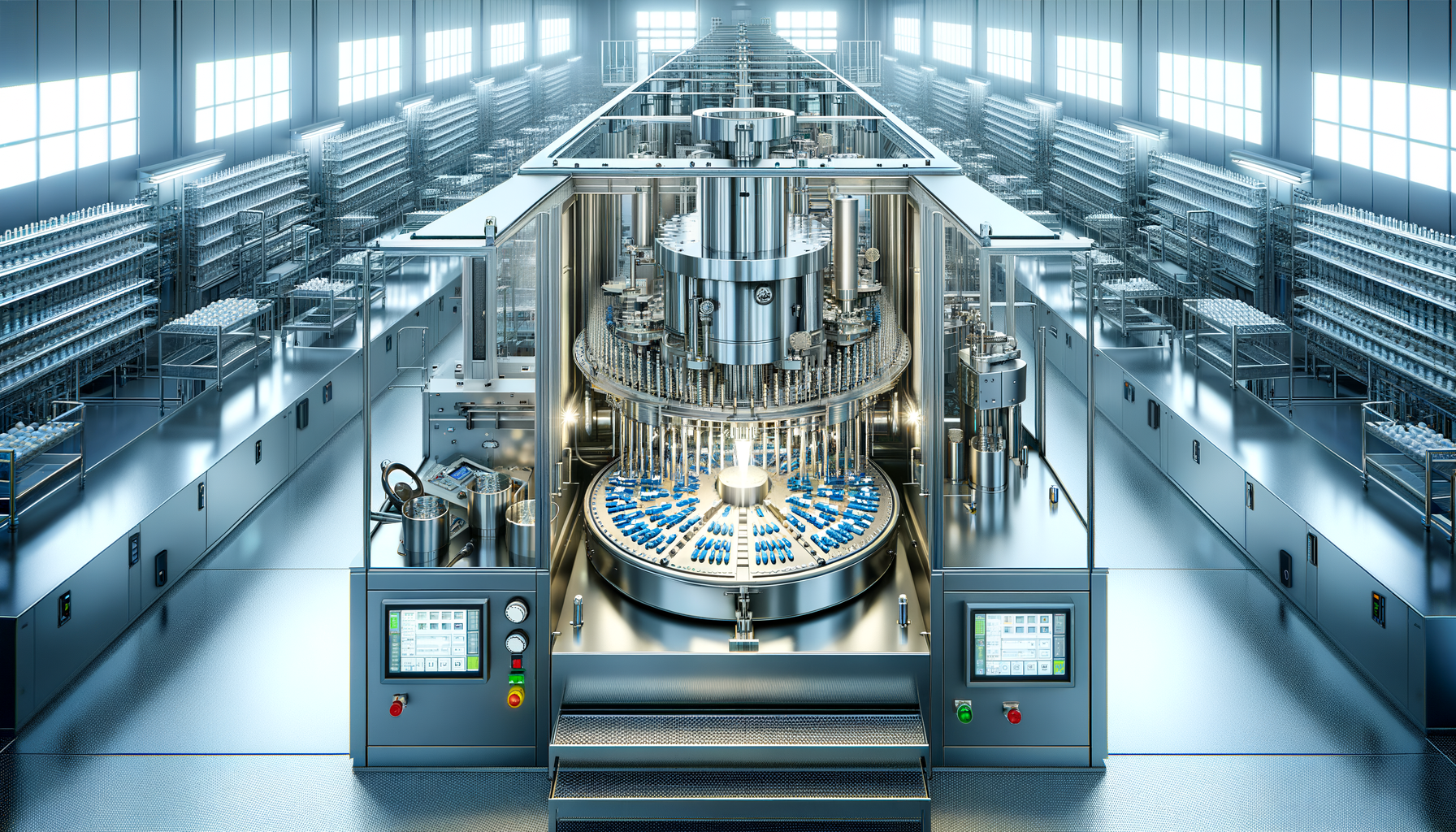

Capsule Filling Machines: Accurate Solutions for Pharma Manufacturing

Capsule filling machines streamline pharmaceutical production by delivering fast, accurate, and contamination-free capsule filling processes.

Introduction to Capsule Filling

In the dynamic world of pharmaceuticals, precision and efficiency are paramount. Capsule filling machines play a crucial role in the industry by ensuring that medications are produced swiftly and accurately. These machines have revolutionized the way pharmaceutical companies operate, offering a contamination-free process that is essential for maintaining the integrity of the medication. As the demand for medication continues to rise, understanding the intricacies of capsule filling becomes increasingly important.

Types of Capsule Filling Machines

Capsule filling machines come in various types, each designed to meet specific production needs. The three main types are:

- Manual Capsule Filling Machines: These are ideal for small-scale production or research purposes. They require human intervention for filling and sealing capsules, making them less efficient for large-scale operations.

- Semi-Automatic Capsule Filling Machines: These machines offer a balance between manual and automatic operations. They require some human oversight but automate significant parts of the process, making them suitable for medium-scale production.

- Automatic Capsule Filling Machines: These are the most advanced and are used for large-scale production. They offer high speed and precision, filling thousands of capsules per hour with minimal human intervention.

Each type of machine has its advantages and limitations, making the choice dependent on the specific needs of the manufacturer. Understanding these differences can help companies select the right equipment for their production goals.

The Capsule Filling Process

The capsule filling process involves several critical steps that ensure the medication is accurately dosed and safely encapsulated. The process typically includes:

- Feeding: Empty capsules are fed into the machine, where they are separated into the cap and body.

- Filling: The medication, in powder or pellet form, is filled into the capsule body. This step requires precision to ensure the correct dosage.

- Joining: The capsule cap and body are rejoined, sealing the medication inside.

- Ejection: The filled capsules are ejected from the machine for further processing or packaging.

Each step in the process is designed to maintain the integrity of the medication, ensuring that each capsule is filled accurately and consistently. This meticulous process is essential for meeting industry standards and ensuring patient safety.

Advantages of Using Capsule Filling Machines

Capsule filling machines offer several advantages that make them indispensable in pharmaceutical manufacturing:

- Efficiency: These machines significantly reduce the time required to produce capsules, allowing for faster production cycles.

- Accuracy: Automated systems ensure precise dosing, reducing the risk of human error.

- Contamination Prevention: The closed system design minimizes the risk of contamination, which is critical in maintaining medication safety.

- Cost-Effectiveness: While the initial investment can be high, the long-term savings in labor and increased production rates make these machines cost-effective.

These benefits make capsule filling machines a vital component in modern pharmaceutical production, enabling companies to meet the growing demand for medications while maintaining high standards of quality and safety.

Future Trends in Capsule Filling Technology

The field of capsule filling technology is continually evolving, with innovations aimed at improving efficiency and precision. Some future trends include:

- Integration with AI: Artificial intelligence is being integrated into capsule filling machines to optimize the filling process and reduce downtime.

- Advanced Quality Control: New technologies are being developed to enhance quality control measures, ensuring even greater accuracy in dosage and capsule integrity.

- Sustainability: As environmental concerns grow, manufacturers are seeking ways to make capsule filling more sustainable, such as using biodegradable materials.

These trends indicate a promising future for capsule filling technology, with advancements that will continue to support the pharmaceutical industry’s need for fast, accurate, and safe production methods.