Magnetic Filtration Systems: Clean Fluids with Precision Separation

Magnetic filtration systems deliver high-efficiency separation of contaminants, helping maintain cleaner fluids in industrial operations.

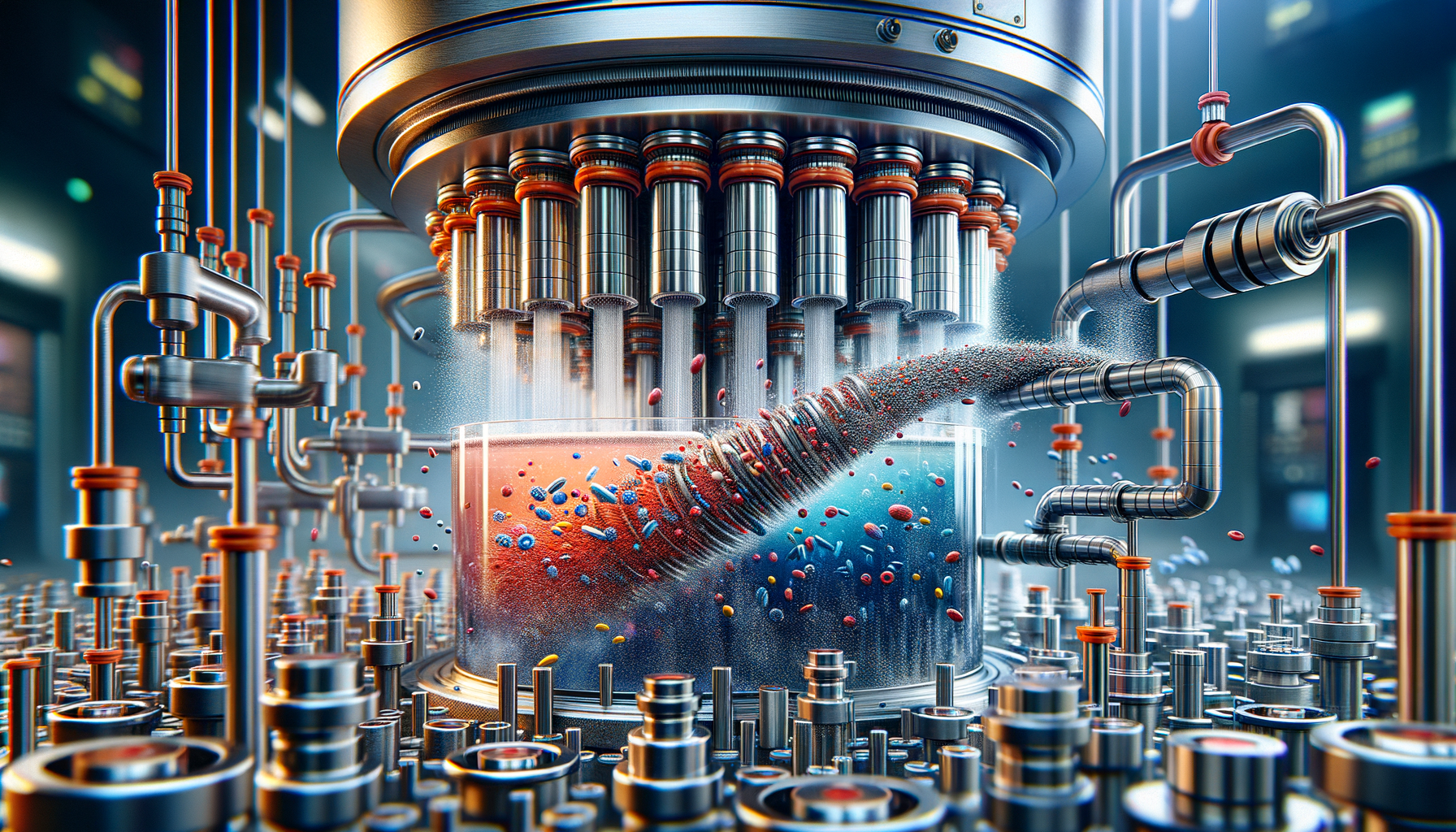

Introduction to Magnetic Filtration Systems

In the realm of industrial operations, maintaining fluid cleanliness is paramount to ensuring the longevity and efficiency of machinery. Magnetic filtration systems have emerged as a pivotal technology in achieving this goal. By leveraging the power of magnetic fields, these systems efficiently separate ferrous contaminants from fluids, thereby enhancing the operational efficacy of various industrial processes. Their relevance is underscored by the increasing demand for precision and reliability in fluid handling applications.

The Science Behind Magnetic Filtration

Magnetic filtration operates on the principle of magnetism, where ferrous particles are attracted to a magnetic field. This process involves the use of magnetic rods or plates placed within the fluid flow, capturing and holding contaminants. The effectiveness of this method is influenced by factors such as the strength of the magnetic field, the flow rate of the fluid, and the concentration of contaminants. By understanding these variables, industries can tailor magnetic filtration systems to their specific needs, ensuring optimal performance.

Advantages of Magnetic Filtration Systems

Magnetic filtration offers numerous benefits over traditional filtration methods. Key advantages include:

- Non-consumable filters: Unlike conventional filters that require regular replacement, magnetic filters are reusable, reducing waste and operational costs.

- High efficiency: Magnetic filters are capable of removing sub-micron particles, ensuring superior fluid cleanliness.

- Minimal maintenance: With fewer moving parts and no need for frequent filter changes, magnetic filtration systems require less maintenance, resulting in reduced downtime.

Applications of Magnetic Filtration

Magnetic filtration systems find applications across a wide array of industries. In the automotive sector, they are used to maintain the purity of lubricants and coolants, enhancing engine performance and longevity. In the food and beverage industry, they ensure the cleanliness of fluids involved in production processes, safeguarding product quality. Additionally, in the pharmaceutical industry, magnetic filtration is crucial for maintaining the sterility and purity of liquid medications.

Future Trends in Magnetic Filtration Technology

As industries continue to demand higher standards of fluid cleanliness, magnetic filtration technology is poised for significant advancements. Innovations such as the integration of IoT (Internet of Things) for real-time monitoring and data analysis are expected to enhance the efficiency and adaptability of these systems. Furthermore, developments in magnetic materials and design are likely to improve the capture rate of contaminants, making magnetic filtration an indispensable tool in industrial fluid management.