Compare High Pressure Nitrogen Compressors options for Industrial Use

Looking for a reliable high pressure nitrogen compressor? Discover top-rated models engineered for consistent performance in demanding industrial environments

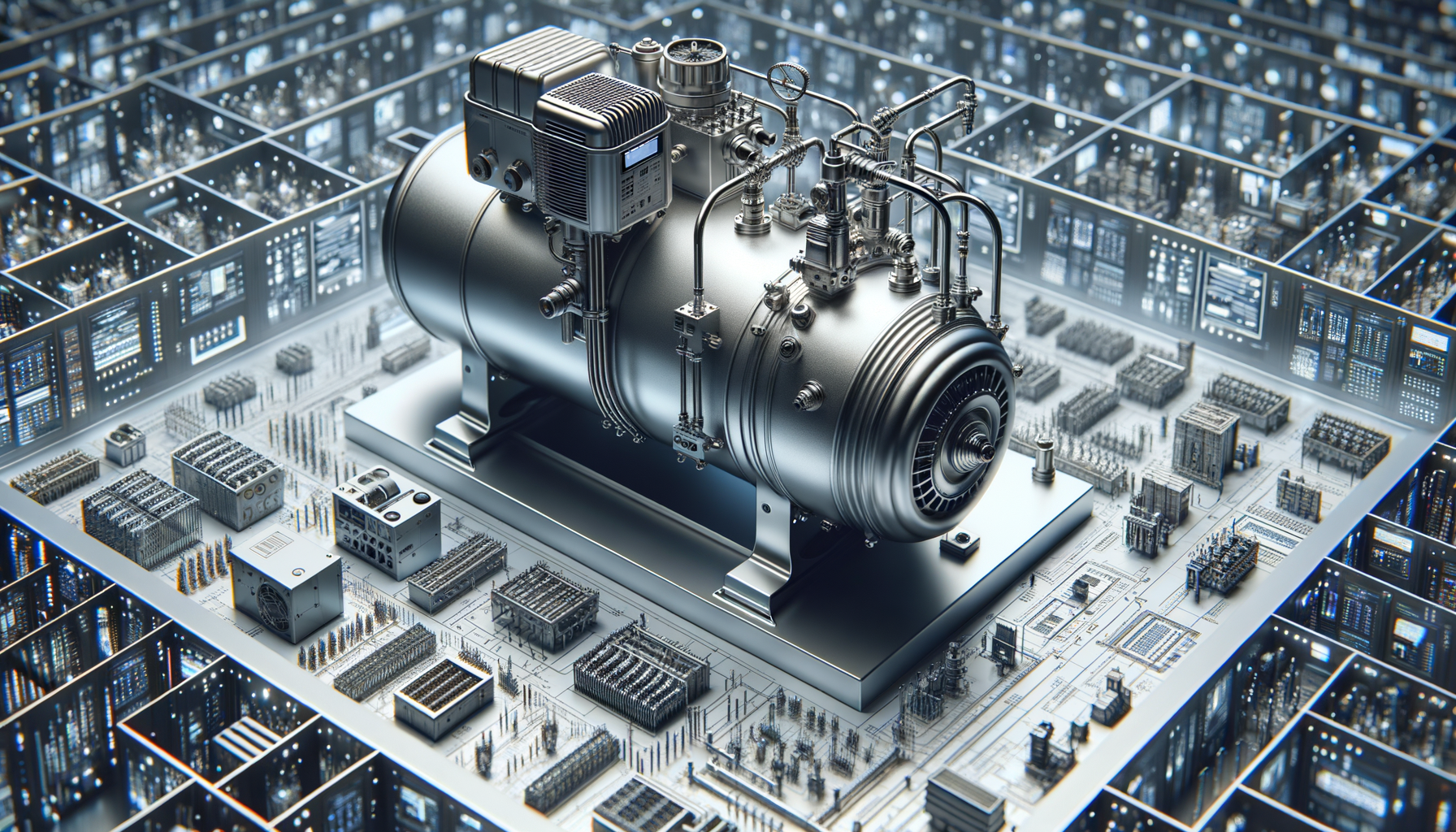

Introduction to Nitrogen Compressors

Nitrogen compressors play a crucial role in various industrial applications, offering a reliable source of compressed nitrogen gas. This gas is essential in fields ranging from food packaging to chemical processing. Understanding the mechanics and benefits of nitrogen compressors can help businesses choose the right equipment to meet their specific needs. In this article, we will explore the significance of nitrogen compressors, especially high-pressure models, in industrial settings and examine some of the top-rated options available today.

How Nitrogen Compressors Work

Nitrogen compressors function by drawing in air, separating the nitrogen molecules, and compressing them to a high pressure. This process typically involves several stages, each designed to increase the pressure of the gas incrementally. The key components of a nitrogen compressor include:

- Intake filters to remove impurities from the air.

- Membrane or pressure swing adsorption (PSA) systems to isolate nitrogen.

- Compression chambers to increase gas pressure.

- Cooling systems to manage the heat generated during compression.

The efficiency of a nitrogen compressor is often measured by its ability to maintain consistent pressure levels while minimizing energy consumption. Modern compressors are equipped with advanced technologies to enhance performance, such as variable speed drives and automated controls.

Applications of High-Pressure Nitrogen Compressors

High-pressure nitrogen compressors are indispensable in industries where precision and reliability are paramount. Some prominent applications include:

- Food and Beverage: Nitrogen is used to displace oxygen in packaging, extending the shelf life of perishable goods.

- Chemical Manufacturing: Nitrogen serves as a protective atmosphere in chemical reactions, preventing unwanted oxidation.

- Oil and Gas: In this sector, nitrogen compressors are used for enhanced oil recovery and pipeline purging.

- Electronics: Nitrogen is employed in soldering processes to prevent oxidation and improve the quality of electronic components.

Each application demands specific compressor features, such as flow rate, pressure capacity, and energy efficiency, making it essential for businesses to evaluate their operational needs carefully.

Choosing the Right Nitrogen Compressor

Selecting the appropriate nitrogen compressor involves assessing several factors to ensure optimal performance. Key considerations include:

- Pressure Requirements: Determine the necessary pressure levels for your application to choose a compressor that can meet those demands.

- Flow Rate: Evaluate the volume of nitrogen required over a specific period and select a compressor with a matching flow capacity.

- Energy Efficiency: Consider models with energy-saving features to reduce operational costs and environmental impact.

- Maintenance Needs: Opt for compressors with minimal maintenance requirements to minimize downtime and repair expenses.

By understanding these factors, businesses can make informed decisions and invest in compressors that align with their operational goals.

Conclusion: Investing in Quality Nitrogen Compressors

In conclusion, high-pressure nitrogen compressors are vital assets in numerous industrial applications. Their ability to deliver consistent and reliable performance makes them indispensable in sectors such as food packaging, chemical processing, and electronics manufacturing. By carefully evaluating their specific needs and considering factors like pressure capacity, flow rate, and energy efficiency, businesses can select compressors that not only meet their operational demands but also contribute to long-term sustainability and cost-effectiveness. Investing in top-rated nitrogen compressors ensures that companies remain competitive and efficient in their respective industries.