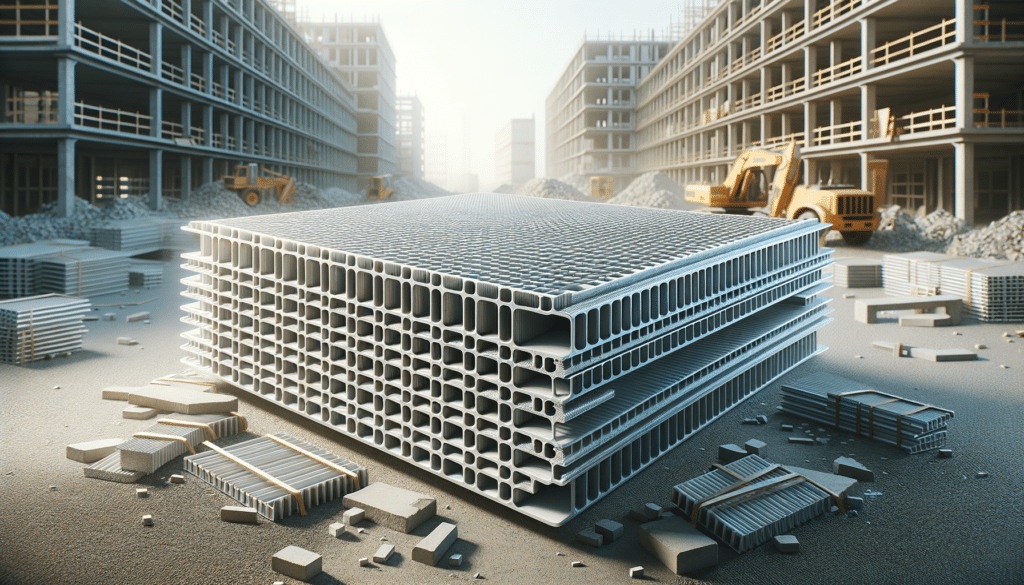

Introduction to Fiberglass Grating

Fiberglass grating has emerged as a critical component in the construction industry, offering a blend of strength, durability, and versatility. Unlike traditional materials such as steel or wood, fiberglass grating provides exceptional resistance to corrosion and environmental stresses, making it suitable for a wide range of applications. The growing demand for sustainable and low-maintenance construction materials has further propelled the adoption of fiberglass grating. This article delves into the various aspects that make fiberglass grating a preferred choice in modern construction projects.

Properties and Benefits of Fiberglass Grating

Fiberglass grating is renowned for its impressive properties that contribute to its widespread use in construction. Some of the key benefits include:

- Corrosion Resistance: Unlike metal grating, fiberglass does not rust or corrode, even when exposed to harsh chemicals or saltwater environments.

- Lightweight yet Strong: Fiberglass grating is significantly lighter than metal alternatives, making it easier to handle and install without compromising on strength.

- Non-Conductive: Its non-conductive nature makes it ideal for electrical applications, ensuring safety in environments where electrical hazards are a concern.

- Low Maintenance: The material requires minimal maintenance, reducing long-term costs and effort.

These attributes not only enhance the functionality of construction projects but also contribute to their longevity and safety.

Applications of Fiberglass Grating in Construction

The versatility of fiberglass grating allows it to be used across various sectors within the construction industry. Common applications include:

- Industrial Flooring: Its slip-resistant surface makes it ideal for factory floors and walkways, ensuring safety and durability.

- Marine Environments: Due to its corrosion resistance, fiberglass grating is extensively used in docks, piers, and offshore platforms.

- Public Infrastructure: Parks, pedestrian bridges, and drainage covers benefit from its lightweight and durable nature.

By integrating fiberglass grating into these applications, construction projects can achieve enhanced performance and sustainability.

Comparing Fiberglass Grating with Traditional Materials

When compared to traditional materials like steel and wood, fiberglass grating offers several advantages. Steel, while strong, is prone to corrosion and requires regular maintenance. Wood, on the other hand, is susceptible to rot and insect damage. Fiberglass grating circumvents these issues, providing a long-lasting alternative that requires less upkeep. Additionally, its lightweight nature reduces transportation and installation costs, offering a more economical solution in the long run.

These comparisons highlight why many construction professionals are choosing fiberglass grating over conventional materials for their projects.

Conclusion: The Future of Fiberglass Grating in Construction

As the construction industry continues to evolve, the demand for materials that are both sustainable and efficient is on the rise. Fiberglass grating, with its exceptional properties and wide-ranging applications, stands out as a material that meets these criteria. Its ability to withstand harsh conditions while maintaining structural integrity makes it a valuable asset in modern construction. As technology advances and the push for environmentally friendly solutions grows stronger, fiberglass grating is poised to play an even more significant role in shaping the future of construction.