High Temperature Industrial Heat Pumps for Demanding Applications

Explore high temperature industrial heat pumps designed for extreme conditions and continuous thermal efficiency.

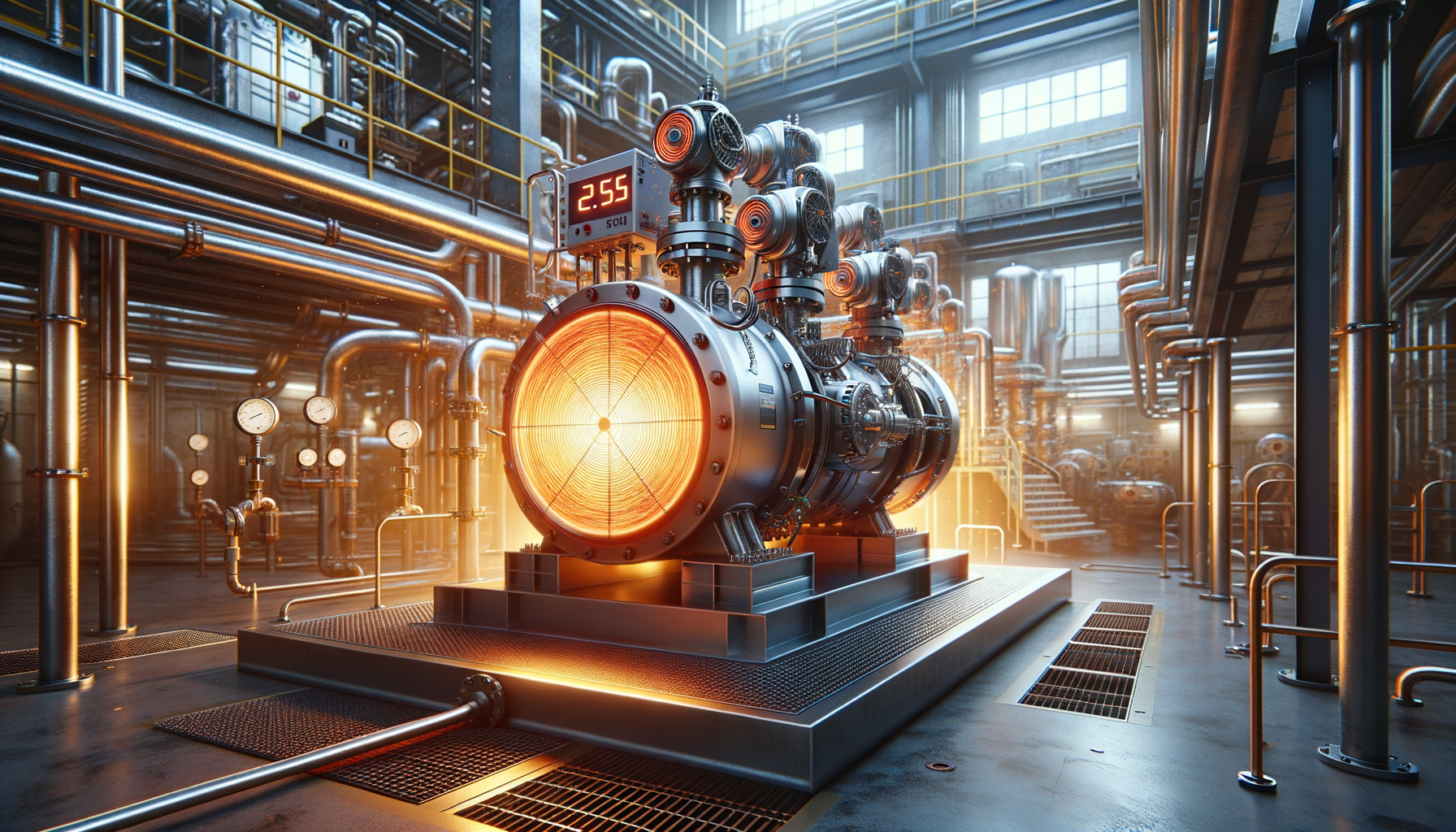

Introduction to Industrial Heat Pumps

Industrial heat pumps are pivotal in modern manufacturing and processing industries, offering a sustainable solution for energy efficiency and waste heat recovery. These systems are engineered to transfer thermal energy from one location to another, often from a lower temperature source to a higher temperature sink, using minimal energy input. The importance of industrial heat pumps lies in their ability to reduce carbon emissions and operational costs, making them an attractive option for industries looking to enhance their environmental credentials.

High temperature industrial heat pumps are specifically designed to operate under extreme conditions, providing reliable thermal management in demanding applications. They play a crucial role in sectors such as food processing, chemical manufacturing, and metal treatment, where precise temperature control is essential. As industries strive to meet stringent environmental regulations, the adoption of high temperature heat pumps is expected to grow, driven by their capacity to improve energy efficiency and reduce reliance on fossil fuels.

Key Features of High Temperature Industrial Heat Pumps

High temperature industrial heat pumps are characterized by their robust construction and advanced technology, which enable them to function efficiently in harsh environments. Some of the notable features include:

- Extended Temperature Range: Capable of operating at significantly higher temperatures than standard heat pumps, making them suitable for applications requiring elevated heat levels.

- Durable Materials: Constructed with materials that withstand high thermal stresses, ensuring longevity and consistent performance.

- Advanced Control Systems: Equipped with sophisticated control mechanisms to maintain precise temperature settings and optimize energy usage.

These features make high temperature heat pumps an invaluable asset in industries where maintaining specific thermal conditions is critical. Their ability to deliver consistent performance under challenging conditions underscores their role as a cornerstone of industrial energy management strategies.

Applications in Various Industries

High temperature industrial heat pumps find applications across a wide range of industries, each with unique thermal management needs. In the food processing industry, they are used for pasteurization and drying processes, where maintaining precise temperatures is crucial for product quality and safety. The chemical industry utilizes these pumps for distillation and reaction processes, which require consistent heat input to ensure efficient chemical transformations.

In the metal treatment sector, high temperature heat pumps are employed in processes such as annealing and tempering, where controlled heating and cooling cycles are essential for achieving desired material properties. The versatility of these pumps allows them to be tailored to specific industrial requirements, making them a versatile tool for enhancing production efficiency and product quality.

Benefits of Implementing High Temperature Heat Pumps

The implementation of high temperature industrial heat pumps offers numerous benefits that extend beyond energy savings. These systems contribute to a reduction in greenhouse gas emissions by minimizing the need for fossil fuel-based heating solutions. By recovering and reusing waste heat, they enhance overall energy efficiency, leading to significant cost savings for businesses.

Moreover, high temperature heat pumps support industries in achieving sustainability goals, aligning with global efforts to combat climate change. Their ability to provide reliable and efficient heating solutions in demanding applications positions them as a key component of sustainable industrial practices.

Future Prospects and Technological Advancements

The future of high temperature industrial heat pumps looks promising, with ongoing technological advancements poised to enhance their performance and applicability. Innovations in materials science are expected to lead to even more durable and efficient systems, capable of operating at higher temperatures and pressures.

Additionally, the integration of smart technologies and IoT capabilities will enable real-time monitoring and optimization of heat pump operations, further improving energy efficiency and reducing operational costs. As industries continue to prioritize sustainability and energy efficiency, the demand for high temperature heat pumps is anticipated to rise, driving further research and development in this field.