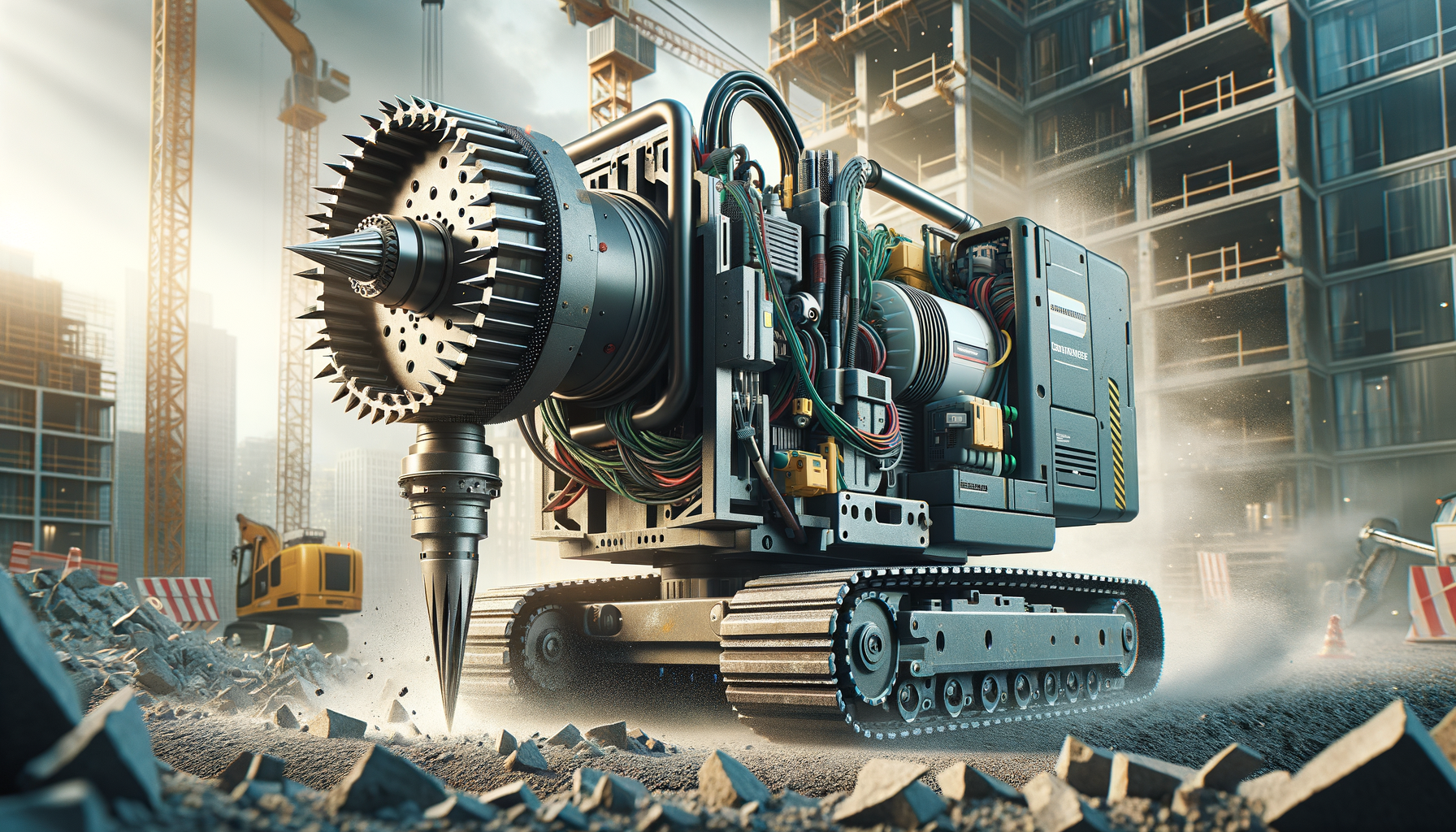

Reliable Cutting Performance in Every Construction Challenge

Core drilling and cutting machine designed for precision and efficiency in various construction and engineering applications, ensuring reliable performance in demanding environments.

Introduction to Core Drilling and Cutting Machines

Core drilling and cutting machines are pivotal in the construction and engineering industries, offering precision and efficiency in a variety of applications. These machines are designed to penetrate hard surfaces, such as concrete and stone, with remarkable accuracy, making them indispensable tools in modern construction projects. The ability to perform precise cuts and drills is essential for maintaining structural integrity and safety, which is why understanding the capabilities and applications of these machines is crucial for professionals in the field.

Understanding the Mechanism of Core Drilling Machines

Core drilling machines operate using a rotating drill bit that is specifically designed to cut through hard surfaces. The core bit, often encrusted with industrial-grade diamonds, is capable of creating clean and precise holes in materials like concrete, asphalt, and masonry. The process involves the removal of a cylindrical core of material, which allows for the installation of pipes, cables, or other structural components.

These machines are equipped with features that enhance their operational efficiency, including:

- Variable speed settings to adapt to different material densities.

- Water cooling systems to reduce heat and prolong the life of the drill bit.

- Adjustable stands for stability and precision during operation.

The versatility and adaptability of core drilling machines make them suitable for a range of applications, from simple home renovations to large-scale infrastructure projects. By understanding the mechanism and features of these machines, operators can maximize their efficiency and effectiveness on the job site.

Applications and Benefits of Core Cutting Machines

Core cutting machines are used in a variety of applications that require precise and efficient cutting capabilities. These machines are essential in construction projects where structural modifications are necessary, such as installing new plumbing or electrical systems. The benefits of using core cutting machines include:

- Precision: The ability to make clean and accurate cuts reduces the risk of damaging surrounding structures.

- Efficiency: Core cutting machines can complete tasks quickly, reducing downtime and labor costs.

- Versatility: Suitable for use on a wide range of materials, including concrete, stone, and metal.

In addition to construction, core cutting machines are employed in industries such as mining, where they are used to extract samples for analysis. Their precision and efficiency make them valuable tools in any industry that requires reliable cutting performance.

Comparing Core Drilling Machines: Features and Considerations

When selecting a core drilling machine, it is important to consider a variety of factors to ensure it meets the specific needs of the project. Key features to evaluate include:

- Power: Machines with higher power ratings can handle tougher materials and larger diameters.

- Portability: Lightweight and compact designs are ideal for jobs that require mobility.

- Durability: Machines constructed with robust materials offer longevity and reliability.

Additionally, operators should consider the availability of replacement parts and the manufacturer’s customer support services. By comparing these features, users can select a machine that offers the best balance of performance, durability, and cost-effectiveness for their specific application.

Conclusion: Investing in Core Drilling and Cutting Machines

Investing in a core drilling and cutting machine is a strategic decision for any construction or engineering professional. These machines provide the precision and efficiency necessary to tackle a wide range of projects, from small-scale renovations to major infrastructure developments. By understanding the features and applications of core drilling and cutting machines, professionals can ensure they are equipped with the tools needed to deliver outstanding results in demanding environments.

Ultimately, the reliability and performance of these machines make them a valuable asset in any construction toolkit, helping to drive productivity and maintain high standards of quality and safety.