Semiconductor Processing Equipment: Solutions for Precision Manufacturing

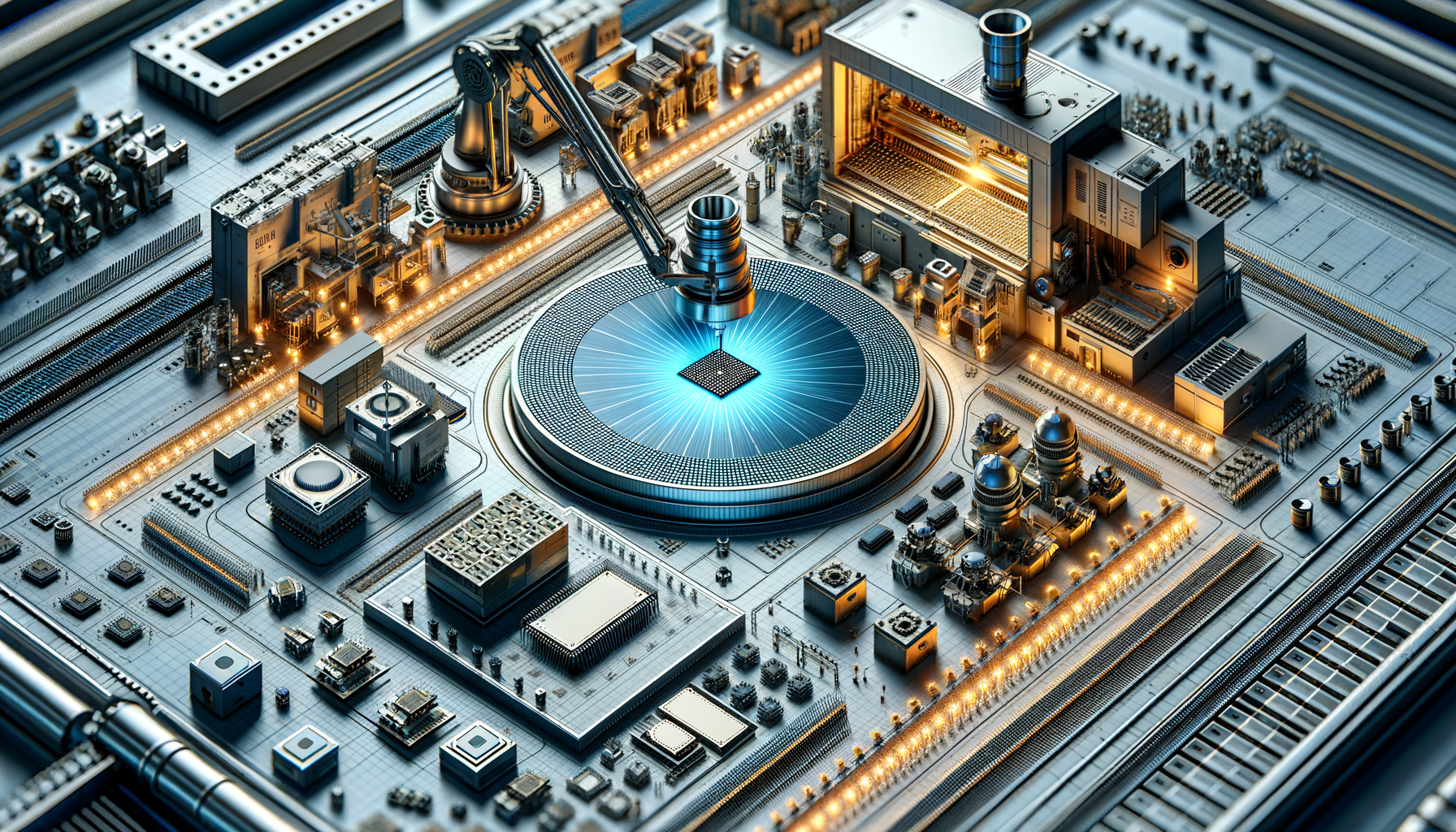

Semiconductor manufacturing relies on advanced equipment that ensures precision, speed, and cleanliness throughout the fabrication process.

Introduction to Semiconductor Processing

The world of semiconductor processing is a fascinating intersection of science, technology, and engineering. It plays a critical role in the production of the electronic devices that power our modern world, from smartphones to supercomputers. The semiconductor manufacturing process is a complex sequence of steps that transforms raw materials into highly sophisticated microchips. Each step requires precision, cleanliness, and advanced technology to ensure the final products meet the high standards required by today’s electronic devices.

Semiconductor processing is not just about creating microchips; it involves a comprehensive understanding of materials science, chemical processes, and physics. The industry has evolved significantly over the years, driven by the demand for smaller, faster, and more efficient electronic components. This evolution has necessitated the development of advanced semiconductor processing equipment that can handle the intricate requirements of modern chip fabrication.

The Role of Semiconductor Processing Equipment

Semiconductor processing equipment is at the heart of chip manufacturing. It encompasses a wide range of machines and tools, each designed for a specific function in the production line. These include equipment for deposition, etching, lithography, and testing. Each piece of equipment must operate with exceptional precision to ensure the chips are manufactured to the exact specifications required for their intended applications.

One of the key challenges in semiconductor manufacturing is maintaining the cleanliness of the production environment. Even the smallest particle of dust can cause defects in a chip, rendering it unusable. Therefore, semiconductor processing equipment is often housed in cleanrooms with stringent environmental controls. These cleanrooms are equipped with air filtration systems, temperature and humidity controls, and special clothing for personnel to prevent contamination.

Moreover, the need for precision in semiconductor processing cannot be overstated. The dimensions of modern microchips are measured in nanometers, meaning that any deviation from the specified measurements can have significant consequences on the chip’s performance. As such, semiconductor processing equipment is designed to operate with extreme accuracy, often incorporating advanced technologies such as laser alignment and computer-controlled operations.

Key Processes in Semiconductor Manufacturing

The semiconductor manufacturing process is divided into several key stages, each involving specific equipment and techniques. These stages include:

- Wafer Fabrication: This is the initial stage where silicon wafers are produced. The wafers serve as the substrate on which the microchips are built.

- Photolithography: A critical process that involves transferring a circuit pattern onto the wafer. This is achieved using a light-sensitive material and a mask that defines the circuit layout.

- Etching: This process removes unwanted material from the wafer, creating the intricate patterns needed for the circuit.

- Deposition: Thin layers of materials are deposited onto the wafer to form the various components of the microchip.

- Testing and Packaging: The final stages involve testing the chips for functionality and packaging them for distribution.

Each of these processes requires specialized equipment designed to perform specific tasks with high precision and reliability. The integration of these processes ensures that the final products meet the stringent quality standards of the semiconductor industry.

Innovations in Semiconductor Processing Equipment

The semiconductor industry is characterized by rapid innovation and technological advancement. As the demand for more powerful and efficient electronic devices continues to grow, so too does the need for more advanced semiconductor processing equipment. Recent innovations in this field have focused on improving the precision, speed, and efficiency of the manufacturing process.

One area of innovation is in the development of extreme ultraviolet (EUV) lithography equipment. EUV lithography allows for the creation of smaller and more complex circuit patterns, enabling the production of more powerful microchips. This technology is essential for keeping up with the trend of miniaturization in the electronics industry.

Another significant advancement is in the automation of semiconductor processing equipment. Automation reduces the potential for human error, increases production speed, and enhances the overall efficiency of the manufacturing process. Automated systems can perform complex tasks with precision and consistency, ensuring that each chip meets the required specifications.

Furthermore, advancements in materials science have led to the development of new materials for use in semiconductor manufacturing. These materials offer improved performance characteristics, such as higher conductivity and greater resistance to heat, which are critical for the next generation of electronic devices.

Challenges and Future Prospects

Despite the advancements in semiconductor processing equipment, the industry faces several challenges. One of the primary challenges is the high cost of developing and maintaining advanced manufacturing facilities. The equipment required for semiconductor processing is expensive, and the need for constant upgrades to keep up with technological advancements adds to the financial burden.

Another challenge is the increasing complexity of semiconductor designs. As electronic devices become more sophisticated, the demand for more complex microchips grows. This requires semiconductor processing equipment that can handle intricate designs with precision and efficiency.

Looking to the future, the semiconductor industry is poised for continued growth and innovation. The development of new technologies, such as quantum computing and artificial intelligence, will drive the demand for more advanced semiconductor processing equipment. Additionally, the push for sustainability and environmental responsibility will lead to the development of more energy-efficient manufacturing processes.

In conclusion, semiconductor processing is a vital component of the modern electronics industry. The equipment used in this process is critical for ensuring the precision, speed, and cleanliness required for the production of high-quality microchips. As technology continues to evolve, so too will the semiconductor processing equipment that supports it, paving the way for the next generation of electronic devices.