Warehouse Automation Solutions for Scalable Efficiency

Automate warehouse operations with scalable systems designed to boost productivity and reduce manual handling.

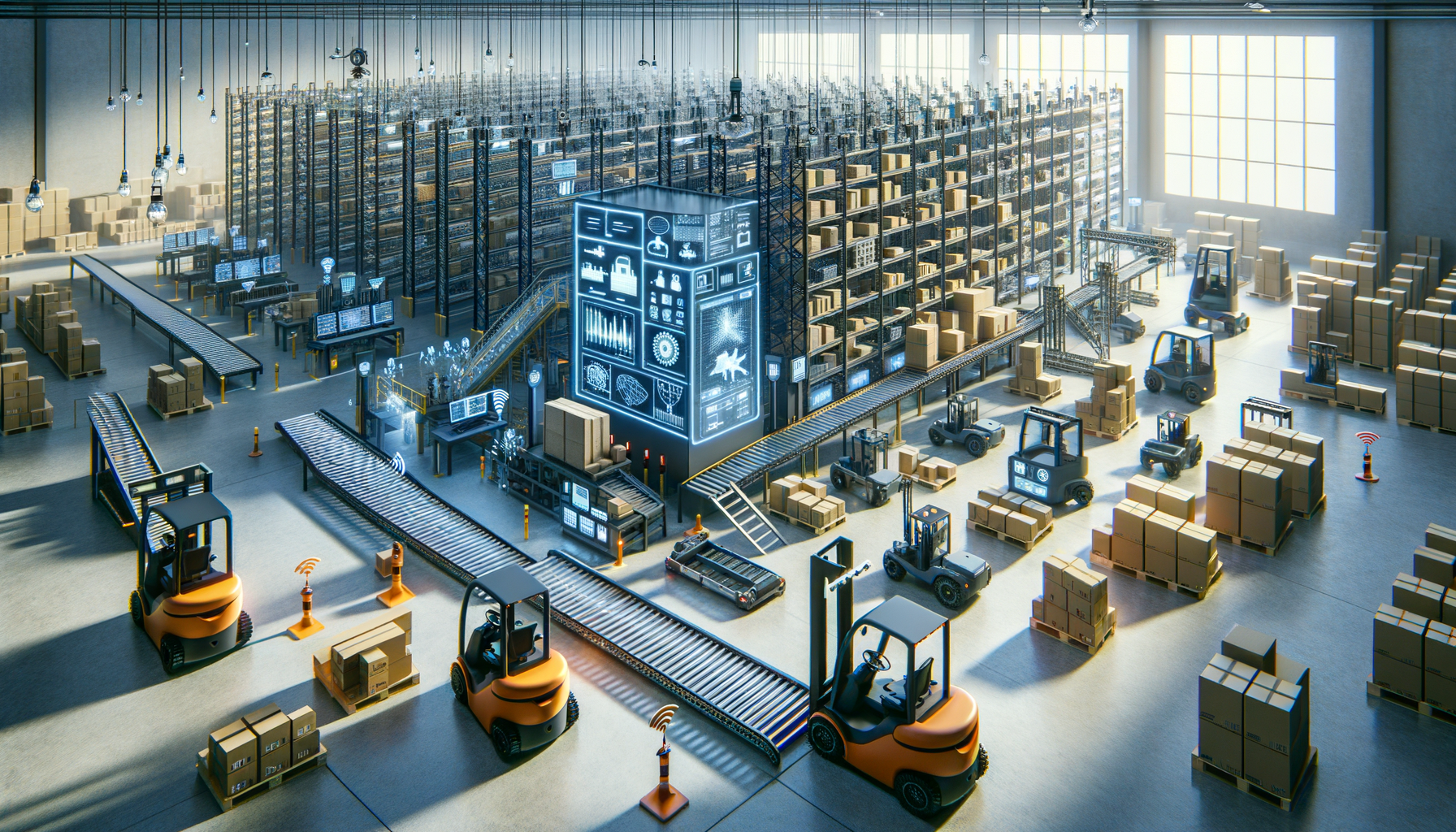

Introduction to Warehouse Automation

In the rapidly evolving landscape of supply chain management, warehouse automation stands as a pivotal innovation. By integrating advanced technologies, businesses can streamline operations, enhance accuracy, and significantly reduce labor costs. Warehouse automation refers to the use of technology to perform tasks that were traditionally carried out by human workers. This includes the use of robotics, automated storage and retrieval systems, and sophisticated warehouse management software. The importance of automation is underscored by the increasing demand for faster delivery times and the need to minimize human error in inventory management.

Key Components of Warehouse Automation

Warehouse automation encompasses a variety of components, each contributing to the overall efficiency of operations. Key components include:

- Automated Guided Vehicles (AGVs): These vehicles transport goods within the warehouse without human intervention, following pre-defined paths.

- Robotic Arms: Used for picking and packing, robotic arms can handle tasks that require precision and speed.

- Automated Storage and Retrieval Systems (AS/RS): These systems automatically place and retrieve items from storage locations, optimizing space and time.

- Warehouse Management Systems (WMS): Software solutions that oversee the day-to-day operations of a warehouse, ensuring efficiency and accuracy in inventory management.

By integrating these components, warehouses can achieve a level of operational efficiency that is difficult to attain with manual processes alone.

Benefits of Implementing Warehouse Automation

Implementing warehouse automation brings a host of benefits that can transform the way businesses operate. Some of the most notable advantages include:

- Increased Efficiency: Automation reduces the time required for tasks such as picking, packing, and shipping, allowing for quicker order fulfillment.

- Cost Reduction: By reducing the need for manual labor, businesses can lower their operational costs significantly.

- Improved Accuracy: Automated systems minimize human error, ensuring that inventory levels are accurately maintained and orders are correctly fulfilled.

- Scalability: Automated systems can be easily scaled to accommodate business growth, making it easier to handle increased demand.

These benefits make warehouse automation an attractive option for businesses looking to enhance their supply chain operations.

Challenges and Considerations in Warehouse Automation

Despite its many advantages, warehouse automation is not without challenges. Businesses must consider several factors before implementing automation solutions:

- Initial Investment: The cost of purchasing and installing automated systems can be substantial, requiring careful financial planning.

- Integration with Existing Systems: Ensuring that new automation technologies integrate seamlessly with existing systems can be complex and time-consuming.

- Workforce Adaptation: Employees may need to be retrained to work alongside automated systems, which can require time and resources.

- Maintenance and Upkeep: Regular maintenance is essential to keep automated systems running smoothly, which can add to operational costs.

Addressing these challenges requires a strategic approach, balancing the benefits of automation with the practical realities of its implementation.

Future Trends in Warehouse Automation

As technology continues to advance, the future of warehouse automation looks promising. Emerging trends include:

- Artificial Intelligence (AI): AI can enhance decision-making processes within warehouses, optimizing inventory management and predicting demand.

- Internet of Things (IoT): IoT devices can provide real-time data on warehouse operations, improving efficiency and accuracy.

- 5G Connectivity: Faster and more reliable internet connections will enable more sophisticated automation solutions, enhancing communication between devices.

- Collaborative Robots (Cobots): Designed to work alongside humans, cobots can enhance productivity by handling repetitive tasks while humans focus on more complex activities.

These trends suggest that warehouse automation will continue to evolve, offering even greater opportunities for efficiency and innovation in the supply chain sector.